|

|

|

|

IMP.A.C.

Liquid Filling Unit (Anti Explosion)

Machine Type

| Container type |

56-SA.4P/1500 |

56-SA/300 |

56-SA/100 |

| Container weight |

(max/min kg) |

1500/50 |

300/5 |

100/2 |

| Pallet dimensions |

(mm) |

1200 x 1200 |

- |

- |

| Container dimensions |

(mm) |

- |

φ600 |

φ400 |

| Height variation |

(mm) |

1000 |

450 |

450 |

| Accuracy |

(g) |

500 |

20 |

10 |

| Throughput/hour |

(n) |

50 |

60 |

80 |

| Compressed |

(nl) |

90 |

60 |

60 |

| Operating compressed |

(bar) |

6 |

6 |

6 |

| Container motion |

manual or

motorised |

| Net total weight |

(kg) |

1300 |

700 |

600 |

IP55 protection

(Power consumption) |

|

0,3kW@230V |

0,3kW@230V |

0,3kW@230V |

Ex-zone1 protection

(Power consumption) |

|

0,2kW@24V |

0,2kW@24V |

0,2kW@24V |

|

| *56-SA.4P1500

The semi-automatic system is ideal when filling chemical

product in drums from 60 to 220 litres or 1000 liters I.B.C.

The system consists in a three-axis mobile filling arm, with

height regulation, capable of filling weight during the filling

operation of each container.

Aspiration for fumes or vapour is available on request.

|

| -60 litres drums |

-1000 litres IBC |

|

|

| -Long nozzle (accessory) |

|

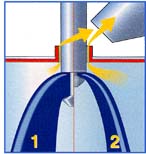

Filling Principle

|

The product is filled, through the

nozzle opening, in two steps: phase one (1), coarse

weight, with full nozzle opening, the product is filled

at maximum capacity. When reaching the pre-set, the

opening is reduced two (2), fine weight, starts, reaching

the final pre-set weight at lower capacity. At the same

time the inert gas, if required, and fumes generated

by product, are aspirated.

|

|

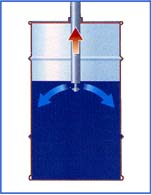

Filling System

| Fixed

height filling for non-dangerous products in open containers. |

|

Variable

height filling for dangerous and/or frothy products in

closed containers, with partial immersion nozzle with

progressive rising during filling. |

|

|

|

|

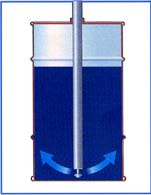

| Fixed

height filling for non-dangerous products in closed

containers. |

|

Fixed

height filling for dangerous and/or frothy products in

closed containers, with full immersion nozzle. |

|

|

|

|

| *56.SA-300/100

The semi-automatic system is ideal when filling chemical

products in drums from 60 to 220 litres or 5-10-25 litres

tanks.

The system consists in a nozzle with height regulation, capable

of filling single containers.

A weighing platform, suspended on load-cells, monitors the

weight during the filling operation of each container.

Aspiration for fumes or vapour is available on request.

|

| |

| -60 litres drums |

-5/10/25 litres tanks |

|

|

|

|